Are you struggling to reduce waste and increase your business’s revenue? Is your company manufacturing products that customers no longer buy? Are you looking for ways to mend your decade-old ways of running the business? All you need to do is start practicing lean management strategies!

The pandemic has negatively affected all businesses worldwide and forced several of them to shut down. So, to succeed in a shutting-down world, companies must find techniques to optimize their resource usage to produce quality products and reduce waste.

But not just any technique will do.

If you want results you haven’t seen before, you need to take steps you haven’t taken before. The market is ever-changing, and competition and customers are evolving. To cope with all the fast-paced changes, you must adopt new strategies to flourish and keep customers satisfied with their services. And one of these strategies is lean management.

Wondering what lean management is? Let’s dive into it!

What Is Lean Management?

Lean management is an iterative project management technique that focuses on increasing a business’s revenue by prioritizing the creation of valuable products for the customer, optimizing the use of the resources to eliminate waste, and establishing a system that keeps evolving along with the customer needs.

In other words, it’s a concept that ensures your business runs efficiently by prioritizing only the most essential products, optimizing resource use, and reducing waste in every way possible.

So, lean essentially has three pillars:

- Delivering value

- Eliminating waste

- Continuously improving

The philosophy at the heart of lean management revolves around the people involved, like customers and their ever-changing needs. It requires businesses to filter their products and services through the customer’s perspective and evaluate what has value and what’s a complete waste of resources.

The concept of value and waste is very well defined in lean management. Waste is any use of funds, materials, time, labor, and resources that don’t produce customer value. However, value is a process or a service the customer won’t be inclined to pay for.

It’s essential to mention that the history of lean goes back to the early 1900s when Henry Ford integrated the lean concept into the manufacturing system; hence, it isn’t a recently developed ideology.

The lean methodology, now famously known as “The Toyota Way,” is derived from the Toyota Production System (TPS), a modified version of Henry Ford’s implementation at Toyota post-WWII to optimize their production and minimize the waste to flourish.

The great thing about this philosophy is that it isn’t specific to a particular type of business or process, it can be tailored to all sorts of businesses, workflows, systems, and personal tasks to make the most of them.

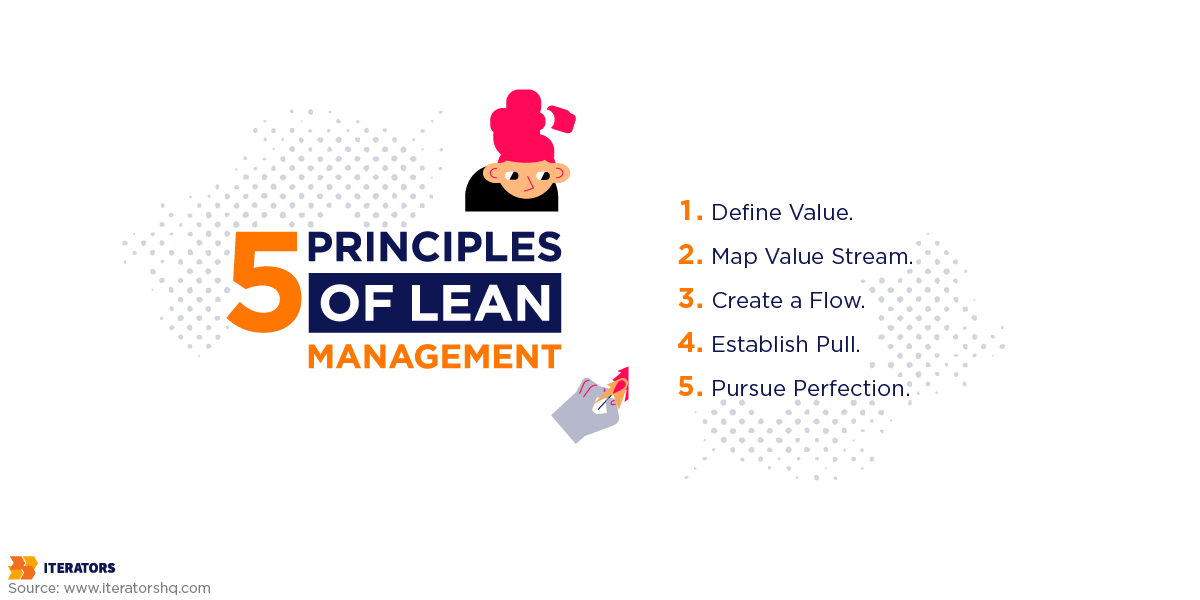

5 Principles of Lean Management

The lean management methodology depends heavily on five principles that enhance each other and become a part of a cycle that runs iteratively to fulfill its objectives. The five principles are:

1. Define Value

This step lays the foundation for the lean methodology and focuses solely on the customer. It revolves around digging deeper into the sales and the customer’s interaction with the product to narrow down what the customer wants. What are they willing to buy? What are they not buying? Why are they not buying certain products?

Sales analysis can be the starting point, but it isn’t enough to get the full picture of the problem. So, valuable feedback can be collected through customer reviews, interviews, surveys, etc. An in-depth analysis of this data will reveal the deal breakers and shed some light on what products or services are of actual value to the customers.

Once you’ve narrowed those down, everything else that your business is offering is considered a waste and gives you an idea of what else needs to be done.

2. Map Value Stream

Once you know your customer’s values, you’ll have to work towards establishing a workflow that delivers the identified values. To ensure that, you’ll have to go over every part of the existing process, service, and product to determine what adds value and what doesn’t. These must be measured in terms of time, effort, employees, and resources.

The mapping of the value stream helps you visualize what is of how much value and makes it easier for you to isolate or eliminate what doesn’t add any value.

3. Create a Flow

Mapping the value stream and eliminating processes that don’t add value isn’t enough to ensure that the process utilizes resources efficiently. So, how can you do that? You have to make sure tasks are divided among teams who are capable and equipped to handle them. You can also split these tasks into chunks that can be completed quickly to save time.

Moreover, it’s your responsibility to check the progress of the various teams and quickly resolve any bottlenecks or hurdles they may face to ensure waste-free production.

4. Establish Pull

The pull system is introduced to minimize waste further during production. This idea is built upon the just-in-time production and delivery approach, so products are only manufactured in needed quantities.

This system will help eliminate inventory, considered one of the major causes of waste, and allow companies to preserve their resources when needed.

5. Pursue Perfection

Continuous growth is the third pillar of the lean management philosophy, so a huge amount of the methodology’s success relies on the efforts made to improve the system. The competition in the market continues to get more intense with every passing day, so you need to review, modify and update the system to succeed continuously.

The first four principles focus on delivering customer value and helping eliminate waste. The fifth principle is essentially the modification of these four principles with time to ensure that they fit the needs of the ever-changing market and are as close to being perfect for your team as possible.

You can work on achieving the above goal by encouraging your team to give feedback, identifying problem areas based on that feedback, and taking necessary, timely actions to improve the efficiency of the workflow. You should never be satisfied by how your business is running, even if it’s smooth because there is always room to grow if you look closely enough.

How to Create a Lean System?

Implementing the five principles discussed above is how you create a lean system. It’s important to know that an efficient lean system will vary from company to company, so you must experiment and evaluate which version works best for your team and your business.

You should start by discussing the adaptation of the lean system with your team so that everybody is on board and willing to participate, as successful implementation won’t be possible without their willingness.

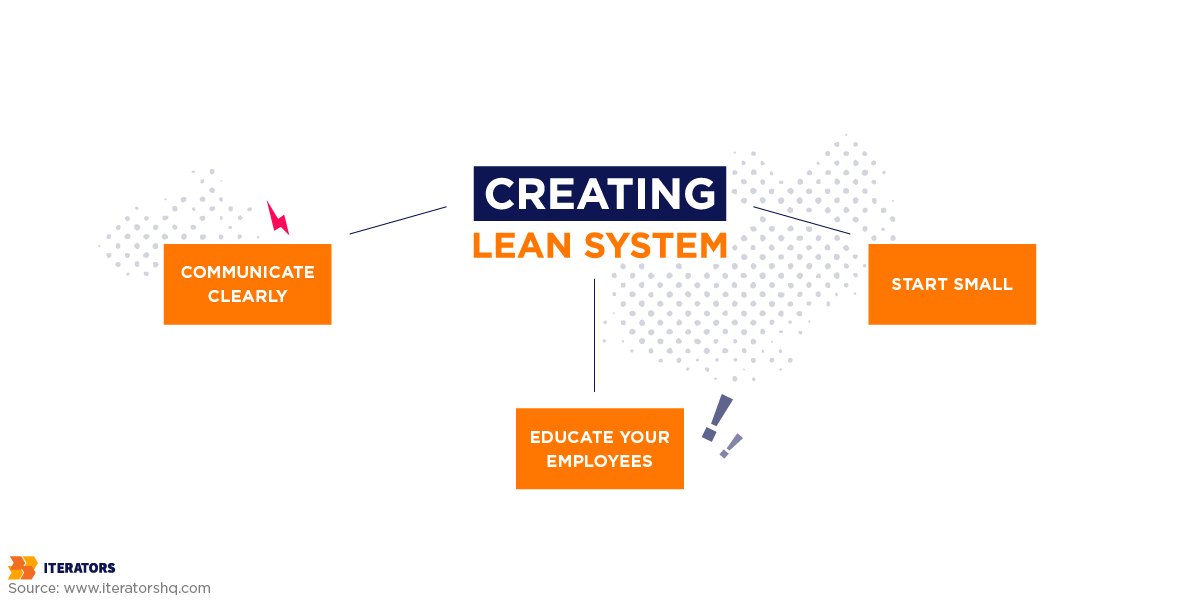

However, before you set out to implement the five principles, you have to:

Communicate Clearly

You should be transparent and clear on why you think it is essential for the company to make the switch. Is the company not making enough profit because of products with low sales? Is your workflow not efficient? Why is it not efficient? Can better products be produced and delivered quickly?

Bring awareness to all the problems you may have and how the lean management approach can fit them. This will motivate people to be more welcoming of the change and encourage them to participate enthusiastically in the company’s growth.

Educate Your Employees

The success of the lean management system relies on the team, so they need to know how it works. They also need to understand what can be done to reap maximum benefits after implementing it.

Furthermore, continuous growth, the third pillar of the methodology, relies on the team’s involvement, and this will only be possible if they understand why it’s so important.

Start Small

Suddenly making a huge shift can overwhelm your employees and cause them to panic, which might slow them down and result in inefficient production. So, it’s best to start with a few people or teams at first, and once they find their rhythm, they can be introduced to more teams until everybody has made the switch.

Benefits of Lean Management

Lean management has played a considerable role in Toyota’s success, but it isn’t the only business that has benefited from incorporating the lean methodology into its production process. Some examples of other companies include Nike, Intel, and John Deere.

Although lean management was first integrated into the automobile manufacturing industry, it works equally well for all types of businesses because it focuses on streamlining every step of the process so that more revenue can be generated and losses through waste can be minimized.

Interestingly, most growing and successful companies use the lean technique without realizing it. For a company to grow, it has to constantly evaluate its production to cut down on waste and produce what is of value to the customer. If you don’t prioritize the opinion and feedback of the customer, your business can’t grow. Hence, lean management is a part of almost every company out there. Some intentionally, some unintentionally.

There are some of the benefits of using this approach:

- Improved Workflow – The process of eliminating unnecessary steps in production reduces the complexity of the workflow, allowing employees to outline what is expected of them.

- Better Utilization of Resources – Optimized workflows and focusing on meeting actual product demand help you realize that many of your employees were wasting their time, effort, and energy on unnecessary tasks.

- Quality Products – All resources now efficiently direct their energies towards adding previously overlooked details, resulting in high-quality products that customers will value even more.

- Reduced Lead Times – Manufacturing processes are streamlined, and businesses can better respond to fluctuations in demand and other market variables, resulting in fewer delays.

- Customer Satisfaction – You can give the customer what they want and need, which means they indulge in purchasing your services with their hard-earned money.

- Financial Benefits – Cutting down costs on waste and producing products that customers will buy helps increase the overall revenue of the company.

- Business Growth – Financial growth and improved customer satisfaction encourage you to invest profit money into expanding and growing your business.

- Sustainability – Your team focuses on constantly learning and evolving, so you’re well-equipped to survive and thrive.

- Employee Satisfaction – Your employees will be relieved of unnecessary tasks, which means they’ll be less burdened. They’ll also feel more satisfied since their opinions will be heard and implemented.

The Different Tools of Lean Management

Lean management is known to have many tools, and they should be used according to their usefulness in each situation. Das et al. (2014) have highlighted some important lean management tools, including:

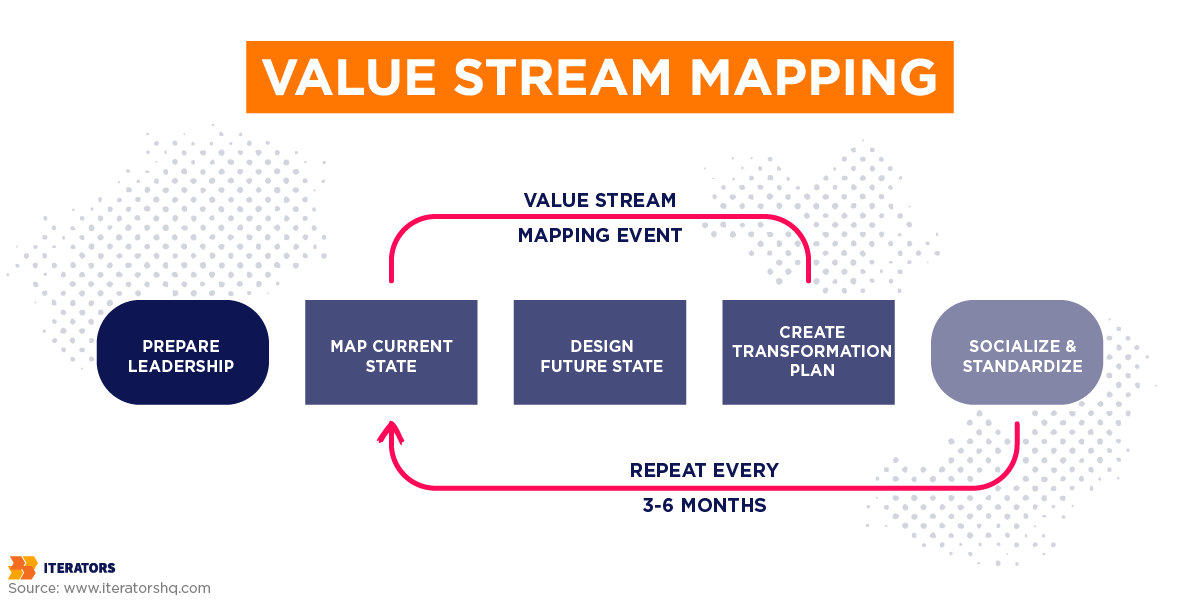

1. Value Stream Mapping (VSM)

Value stream mapping is lean’s most powerful tool. It analyzes, manages, and designs the flow of materials needed to bring a product to the customer.

VSM displays all critical steps in a specific process and determines the time and volume at each stage.

2. 5S

The “5S” name is derived from the Japanese words “Seiri,” “Seiton,” “Seiso,” “Seiketsu,” and “Shitsuke,” which in English are “Sort,” “Set in Order,” “Shine,” “Standardize,” and “Sustain.” Its purpose is to remind employees to use these five senses daily in their workplace.

3. Total Productive Maintenance (TPM)

TPM is a tool to ensure all employees and improvement equipment are utilized to achieve perfect production. It increases production efficiency and reduces waste.

4. Single Minute Exchange of Dies (SMED)

SMED is a lean approach that minimizes setup time in a process that can be accomplished in less than 10 minutes. Its primary purpose is to reduce any wastage of time during a process. SMED helps increase productivity and enhances product quality.

5. Just-in-Time (JIT)

JIT is a management strategy that ensures a company receives goods when they need them to prevent having to stock up and avoid the cost of maintaining them. It’s a successful cost-cutting inventory strategy.

Similarities and Differences Between Lean Management (LM) and Business Process Management (BPM)

Business process management (BPM) and lean management (LM) are known for constantly improving organizational performance. Elzinga et al. (1995) have defined that BPM’s initial stage is to set goals for the company. At this stage, the missions and objectives of the organization are mapped out, and key result areas are determined.

Karim and Arif-Uz-Zaman (2013) have cited that the value stream mapping (VSM) tool is used to calculate the cost and lead time reduction indexes through PDCA (plan, develop, check and analyze). The PDCA cycle is repeated throughout for process improvement.

As the lean management tools have been discussed above, let’s look at some BPM tools for a better understanding. Value Stream Analysis (VSA), Cause-Effect Analysis, Quality Function Deployment (QFD), and Pareto Analysis are some BPM tools. The Value Stream Analysis tool determines which unnecessary activities need to be eliminated. The rest are classified into some other categories. Cause Effect Analysis describes the reasons for a recurring issue that hurts the level of performance. Quality Function Deployment is an approach to discovering the customer’s needs and planning accordingly to meet those needs. Pareto Analysis identifies those smaller factors that led to bigger defects. This tool identifies which problem should be dealt with first.

Choosing Between Lean and BPM

BPM and LM both have common features and rely on continuous improvement. They have the potential to elevate product quality, reduce waiting times, and bring great changes in cost reduction. However, both methodologies can’t be implemented together because BPM uses a top-down view, while LM utilizes a bottom-up view.

So, which one should you choose? According to Mauricio Uriona Maldonado et al. (2020), your choice must be made based on the main flow type of interest: in organizations in which the most important flow and results produced are mainly information, then BPM is recommended, whereas in organizations with greater interest in physical flows, then LM methodology is better.

Their literature review also mentioned that most LM cases were found in manufacturing industries, such as food, automotive, aviation, capital goods, and others, with the main aim of reducing or eliminating waste and improving value-adding activities, even though an increasing trend was observed in service-related industries, such as IT, education and a particular highlight on healthcare applications.

The Bottom Line

While on the BPM side, most cases were found in the service industries such as software, education, banking, not-for-profit, construction, and healthcare, none of the cases reviewed were from the manufacturing industries. A better understanding of BPM and LM methodologies will help you choose your strategy.

Already decided on your management strategy? At Iterators, we can help design, build, and maintain custom software solutions for both startups and enterprise businesses.

Schedule a free consultation with Iterators today. We’d be happy to help you find the right software solution to help your company.