Building a successful business is a never ending process.

It is as much true for smaller companies that are just getting started, as it is for huge, international corporations.

Whether it is productivity, operations or communication, there is always something you can improve on.

But how does this process happen?

Organizational changes can take different forms, they can occur as a major transformation, but most of the time it’s a slow, gradual process that can take years.

One of the examples of such a change is operational excellence.

Even though all of this might sound like a non-descriptive, corporate word salad, operational excellence is actually a pretty important and palpable concept. What’s more it has proven to be an essential growth strategy.

In this article we’ll try to explain and uncover the meaning behind operational excellence and take a closer look at:

- What is operational excellence

- What are the different methodologies used to implement it

- How to achieve operational excellence

- Examples of operational excellence and how companies have historically approached this concept

As Iterators, we have been helping companies make steps to achieve operational excellence and optimize their processes for years. We designed, built, and maintained custom software solutions for both startups and enterprise businesses.

Schedule a free consultation with Iterators today. We’d be happy to help you find the right software solution to help your company get closer to achieving operational excellence.

What is Operational Excellence

Operational excellence is a management strategy that involves maximizing the efficiency of the processes within an organization. It involves being more reliable and performing better than your competition. That includes growing revenue, lowering costs, and instilling a company culture that promotes continuous improvement.

Operational excellence is a concept that builds upon many other management approaches, including:

- Shingo

- Lean Manufacturing

- Six Sigma

- Kaizen

- Hoshin Planning

- Scientific Learning

- Balanced Scorecard

- OKAPI

As a concept operational excellence is somewhat ephemeral. It doesn’t have a single, universally agreed upon definition. And it shouldn’t.

Why?

Because for each company operational excellence may mean different things.

Try looking at it as a set of directives and a general strategy for managing a business.

With the ultimate goal being: the overall improvement of the functioning of your company in all areas.

Operational Excellence: Key Components

Let’s dive deeper into the concept of operational excellence and analyze its key components.

There are two foundational elements to operational excellence, as far as the implementation goes:

- Integrated Management System (IMS) – a framework that includes processes and standards, unique for every organization. Those standards should include the direction of where the company is going, risks of getting there, and strategies of mitigating it. Having an IMS can benefit the company by reducing operational and communication issues and effectively eliminating redundancies and conflicts.

- Operational Discipline Culture – “doing the right thing, the right way, every time”. The second component was built upon the principles of the US Nuclear Navy, and it regulates the operational discipline culture and ensures high reliability of an organization. These values are basically guidelines for what’s expected of each employee and how they should behave to keep up with the company goals.

The importance of Operational Excellence

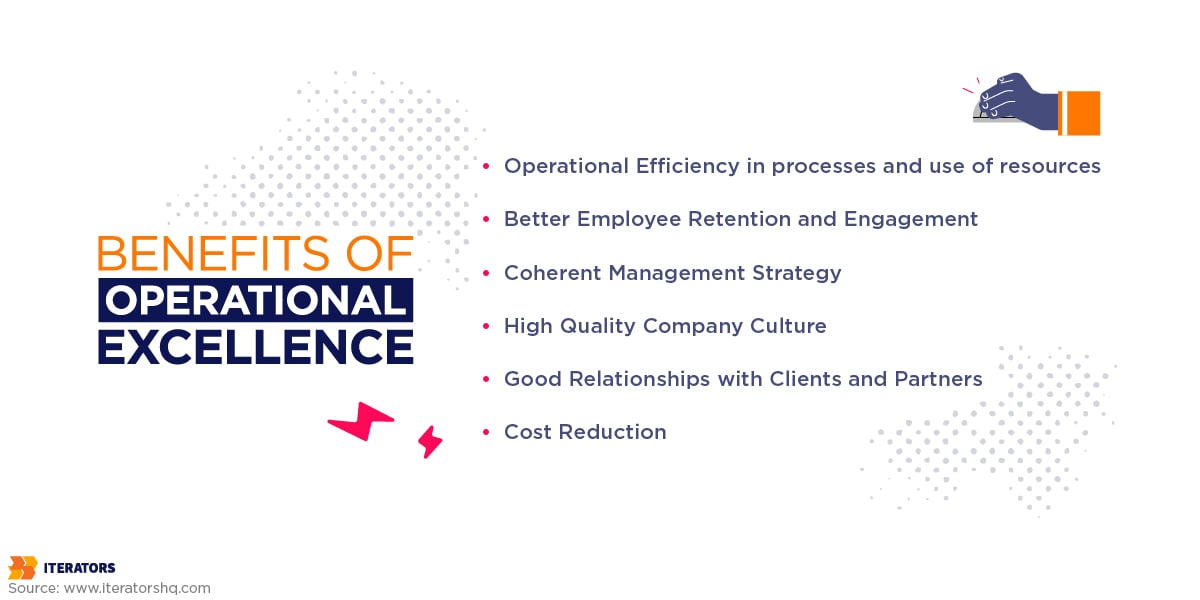

The results of compounding improvements to your business may turn out to be your unfair advantage. If you manage to introduce some change to your company based on the operational excellence principles, you may see yourself leaving the competition in the dust in terms of productivity and growth.

In particular, you can see the following effects on your business:

Flexibility: Operational excellence tactics help to prepare your company for anything – no matter if the times are prosperous or not. While being agile is easier for smaller companies, operational excellence principles help to create the proper environment for adaptation to the ever-changing business landscape.

Better productivity: Perfecting your operations and processes, working on your value streams, and minimizing the waste are certainly the main focus of operational excellence. By honing those, you will be able to deliver a better value to the customer at a better cost, which ultimately leads to better profits for your company.

Growth: Expanding your business once you’ve successfully implemented the principles of operational excellence to your company culture becomes easy. Opening new offices, and training new employees is that much easier when you develop standards and optimize your operations.

Employee Retention: Operational excellence methods emphasize the importance of empowering your employees, letting them participate and influence the life of your company, which translates into more inclusive and vibrant company culture, attracts employees, and inspires them to stay.

Operational Excellence Methodologies

As mentioned in the beginning of this article – operational excellence doesn’t have one, universally agreed upon definition. It may mean different things to different people, depending on the business size, industry etc.

In practice operational excellence is often achieved through implementation of various methodologies. Whether you decide to apply a combination of those or strictly follow just one is entirely up to you and should be decided case by case.

For instance, the American Red Cross ran a massive training program that involved over 50,000 courses being delivered to over 530,000 individuals. It was very challenging to analyze all of the data points and zero in on any specific areas for improvement.

The American Red Cross was able to gain significant operational efficiencies by implementing an integrated tech stack, which included a mobile workforce solution. This is a set of technologies that allows them to reduce their time to schedule and lower their costs.

That said, let’s dig deeper and analyze some of the most common operational excellence methodologies.

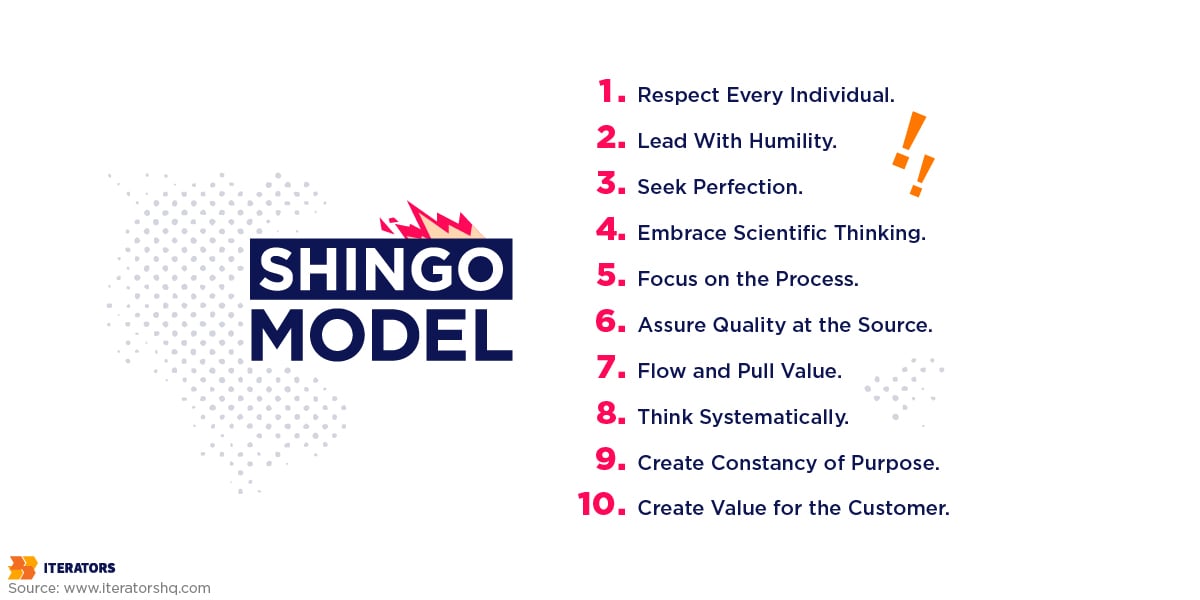

Shingo Model

Shingo model is one of the most quoted and prevalent methodologies when it comes to operational excellence. It was developed by a Japanese engineer Shigeo Shingo and dates back to the 1970s.

Shingo Institute in Utah grants the Shingo Prize every year. The award goes to the company that best represents the principles of this methodology.

- Respect every individual

The Shingo model recognizes that everyone has potential and should be treated with respect. This applies to everyone that is involved in the process, including customers, suppliers, partners, and whatever community you’ve built around your brand. Respect is the foundation of a responsible and ethical business and as such, it is the driving force behind your employees becoming invested in working towards desired outcomes.

- Lead With Humility

Being humble as a leader is extremely important as you should be an example for all the employees. Willingness to listen, include suggestions of others despite their status in the company is a great practice that builds trust among employees.

- Seek Perfection

Nobody is perfect. But striving to be, either as a company or as an individual, is what operational excellence is all about. Set the bar high and look for long-term solutions that are effectively nullifying the problem, instead of quick fixes.

- Embrace Scientific Thinking

Whatever decisions you’re making, they should be derived from empirical data, rather than instincts and hunches. You may not always get to where you want to be, as you will face situations where data is either inconclusive or incomplete. But constant experimentation and learning are a part of the Scientific Thinking process.

- Focus on Process

Concentrating on process improvement is one of the key paths to operational excellence. A transparent and well thought out process helps to smooth out any communication conflicts, which are one of the main causes of inefficiencies.

- Assure Quality at the Source

High quality is a natural consequence of well-structured processes. That said, assigning roles and responsibilities from the very beginning and leaving little to no space for disputes and communication errors will certainly go a long way when you want to ensure high quality.

- Flow and Pull Value

Keeping the process continuous and making sure there is nothing that can interfere with it should be a priority when you are striving to achieve operational excellence. This helps to ensure that your company is providing the maximum value to your customers.

- Think Systematically

Understanding your entire organization is a living, breathing organism, and figuring out the connections and flows within it is absolutely essential to introducing the necessary improvements. Any decisions regarding the changes in your company should be based around solid understanding of the relationships between particular departments.

- Create Constancy of Purpose

The goals of your company should be transparent and laid out clearly for your employees from their first day in the company. A target-oriented and ambitious approach is necessary to create the right environment for growth and improvement.

- Create Value for the Customer

This may sound like a cliche, but it is the customer needs that should guide the development of your product. Remember that achieving operational excellence is directly linked to supplying maximum possible value to your customers in a continuous and efficient manner.

OKAPI Method

The Okapi methodology was developed by Iris Tsidon and Maya Gal – experts working in the field of organizational intelligence. It involves identifying the obstacles facing businesses that strive to achieve operational excellence.

Okapi method consists of two foundational elements – SMART KPIs and a list of challenges facing operational excellence implementation.

Let’s take a closer look at what all of that means.

- Specific: Be precise about your KPIs, the more precise the goals, the better quantifiable the results.

- Measurable: Remember that KPIs should be measuring things that are measurable – focus on actions vs behavior

- Achievable: You want to be ambitious, but also realistic.

- Relevant: KPIs should mirror your business objectives and be relevant to what brings you closer to your success.

- Timely: There needs to be a specific timeframe for every assignment, with a clear set date of completion

The second part of OKAPI is defining the challenges that all companies are facing.

- Disconnect

When your company goals are not aligned with the professional goals of your employees and they are not inspired to achieve them you have a problem. Employees will disconnect and just work to run out the clock. Overcoming the indifference and creating the right goals is a challenge, but it’s absolutely necessary to achieve operational excellence.

- Lack of progress

Lack of progress is connected to bad management, inconsistent business strategy, low morale of employees, and wrong prioritization. Even if your employees are working very hard, it’s not going to bring any results if the processes are not well established.

- Unable to change to stay competitive

Staying competitive can be hard. In an ever-changing business landscape adaptation is the name of the game. If your company is to succeed, you need to have the proper infrastructure in place to adapt quickly and efficiently to stay competitive.

- Data is too complicated to understand easily

Many companies have a lot of disparate data coming from different sources and they have problems consolidating it and drawing the right conclusions. Make sure you introduce a system that will help you read the data effectively because data analysis is the key for making well-informed business decisions.

- No coherent management plan

Lack of consistent and well-thought-out management strategy leads to being wrapped up in day-to-day problems and minor issues, instead of focusing on the big picture. Business development and customer acquisition are important, but if you’re managing a solid group of people you have to know how to delegate.

Fun Fact: Okapi method is named after an animal, which carries traits of a giraffe, dear, and zebra.

Flawless Execution (FLEX)

FLEX, also known as Plan-Brief-Execute-Debrief (PBED) was originally a practice developed by fighter pilots. It was, by all means, an IMS, and it was developed to help them achieve operational excellence in combat. Around 1998 it was adopted as a business practice, but elements of that methodology are used in different industries.

FLEX is an iterative process that emphasizes adaptability through the practice of debriefing. It is a tool that enables cultural changes within organizations, because it eliminates the rank and focuses on evaluating the results of groups or individuals tasked with specific objectives.

FLEX consists of the following steps:

- Plan – the planning phase is the most important and time-consuming part of the method. The plan defines the long-term strategy and specifies a goal. It includes six steps:

- Set a clear team objective

- Identify the threats and risks to achieving the objective

- Identify resources for reducing threats

- Apply Lessons learned

- Break down the objective into individual tasks

- Contingency Plan

- Brief – after the planning phase is complete, the execution team is briefed and the plan has to be communicated to them in detail.

- Execute – objective-oriented execution of the plan

- Debrief – during the debrief phase you have to analyze and measure the results of the execution vs. the plan and make adjustments if necessary.

The premise of the Flawless Execution method is practicing simplicity over complexity, with an army-like rigor. Self-awareness in assessing mistakes and adapting in order to achieve the objective has the highest priority.

Kaizen

Kaizen is another methodology that operational excellence draws from. Kaizen means literally “change for the better” or “improvement” in Japanese and it is a popular concept that has been applied in many process-oriented industries including logistics, healthcare, banking, psychotherapy or life-coaching.

According to the Kaizen Institute there are 5 foundational principles for Kaizen:

- Know your Customer

It may sound like a cliche, but identifying and continuously monitoring the needs and expectations of your customers is absolutely critical to any operational excellence strategy. It should be the foundational element of any of your improvement tactics, as the customer is the final validation of the existence of your business.

- Let it Flow

Everyone in your organization should practice waste elimination and aim to create the most value. While total waste elimination may not be feasible, it’s the striving that’s important. After all, if you could reduce waste to zero – there would be no improvement. And Kaizen implies the improvement is a continuous process, therefore.

- Go to Gemba

Gemba means “real place” in Japanese. In this case, it refers to the leadership and following everything that is happening in your organization. Wherever the value is created, that’s where you need to be.

- Empower People

Organizing your teams and providing them with goals, systems, and tools to meet them is another foundational principle of Kaizen. Company leadership should make it their priority to express the objectives clearly and provide all the support necessary to achieve them.

- Be Transparent

Any performance improvements should be based on factual data. This applies to every stage of the process, whether you’re before making a decision about improvement or after, you should always have metrics that measure your success.

Six Sigma

Six Sigma is a set of principles and practices that guide business process improvement. It was developed by Bill Smith back in 1986 when he was employed at Motorola.

Six Sigma has become one of the most prevalent methodologies when it comes to management and process improvement, with 82% of Fortune 100 companies using it.

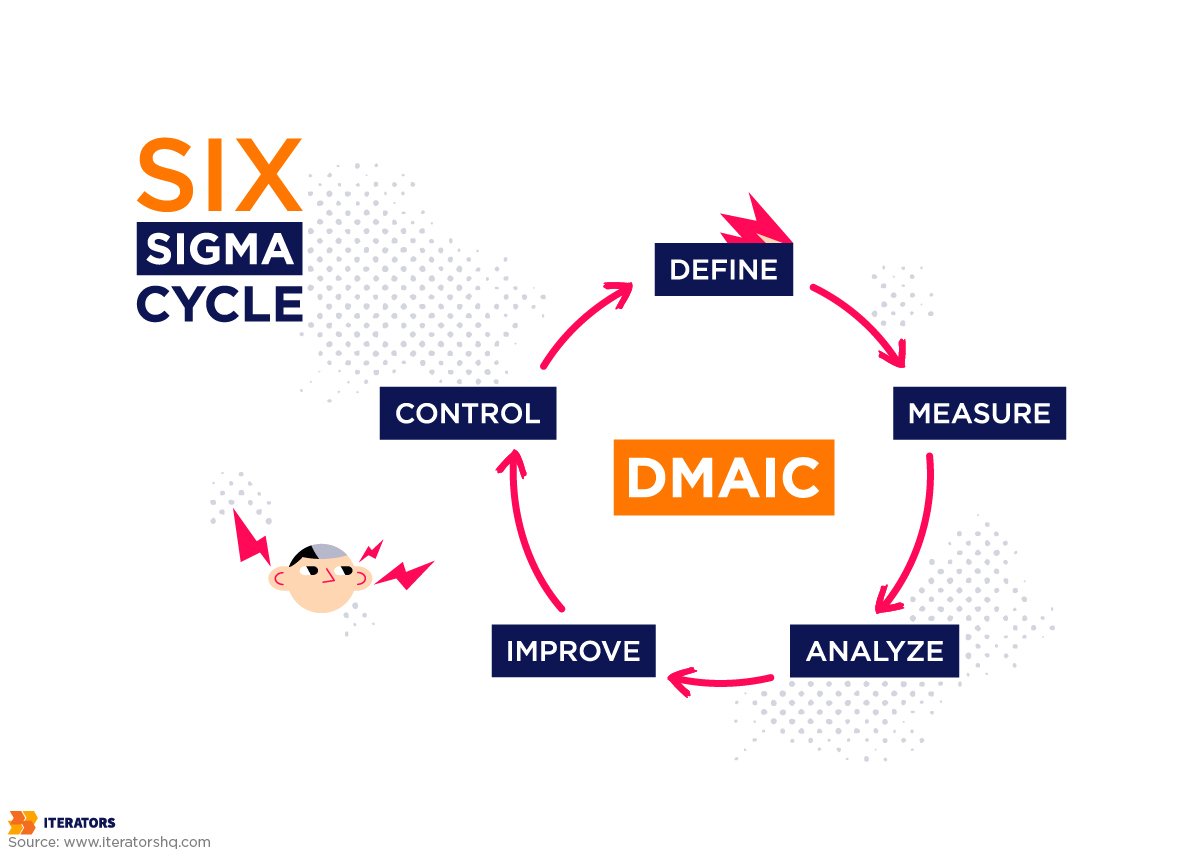

The core concept of the Six Sigma methodology is DMAIC, which stands for:

Define – The first step to solving an issue is defining the problem. Once that phase is complete and the problem is identified and clearly defined you can move on to create a plan.

Measure – Once the issue has been identified, you should measure all the data that is available to you to make sure whatever decisions you will make regarding the process are data-driven and well informed.

Analyze – When all the data is measured and the problem is defined you can analyze your data and try to deduce the possible cause of the problem

Improve – After going through all the data and analyzing the problem you should have a better understanding of the possible solution to your problem. This stage should result in a decision to make a specific change within the process.

Control – This stage is about maintaining control over the process. Making a change is important, but you also need to be mindful of the possible deviations from the objective. That’s why controlling and monitoring the already improved process is a guarantee of continuous results.

Lean Manufacturing

Another methodology that’s important for operational excellence is lean manufacturing, also known as lean production.

The practice of lean manufacturing is defined by waste minimization and productivity maximization. Waste being anything that doesn’t add value for the customer or the brand.

While the definition of what the goals of lean manufacturing are may be different depending on who you ask, it always oscillates between increasing profit or benefitting the customer.

And how do you get there?

By implementing five principles of lean manufacturing:

- Value

Value is created by the product, but it’s based on your customer’s needs and expectations. That’s why customer feedback is a powerful tool that can help you identify which parts of the production process may be redundant or unnecessary. That’s the first step to a solid waste reduction strategy.

- The Value Stream

This stage involves analyzing your value stream, which is the flow of resources needed to generate a product or service. This phase emphasizes identifying potential wasteful practices and ways a process can be improved.

- Flow

Creating a continuous product flow is essential to the success of waste elimination. One of the most important functions of lean manufacturing is preventing disruptions within the product process and taking full control over it.

- Pull

Pull systems are established to efficiently generate the product whenever there is a demand for it, as opposed to pushing systems that are based on the forecasts and determined in advance. The thing with the push systems is that they often lead to overproduction and waste because the forecasts tend to be inaccurate.

- Perfection

All the methodologies of continuous improvement are striving for perfection and Lean Manufacturing is no different. The final guiding principle here is related to targeting the cause of the waste and eliminating it, thus bringing forth improvements.

Lean Manufacturing can be effectively implemented when there is clarity regarding the definition of what is waste. Whether it is industrial manufacturing or software development, the production process is often complex and involves many steps. Therefore finding waste can be a tedious task.

Lean Manufacturing aims to streamline the process of waste elimination and focuses on identifying the most common waste types.

How to Achieve Operational Excellence

Based on the aforementioned methodologies it is safe to say that there are a few ways an organization can achieve operational excellence. At this stage, you should be ready to create an operational excellence program that will be tailored to your specific needs.

Let’s take a closer look at the common denominators – steps that are similar for each of the theories, and sketch out a plan of implementation:

- Organize

Start by assembling the team, assigning roles for each member, and informing them about the objectives and vision of your improvement. A good brainstorming session may also uncover some extra insights and help you make the plan more effective and complete.

- Assess and Document

The first step towards improvement should always be a thorough analysis of your value stream. It involves checking and documenting the flow of resources needed to generate your product or service.

- Identify Improvements

When the analysis is complete, you can start identifying possible improvements based on the factual data that you’ve gathered. Highlight the changes that need to be made within the organizational culture and document the project steps. Make sure you focus on the areas that have the highest potential for improvement.

- Set Goals

Once you know more about which areas you should improve, you have to set up precise and realistic goals, create a timeline, and most important KPIs. Finally, assign members of your team that will be responsible for measuring all the metrics and documenting the progress.

- Execute

Coordinate with management and the rest of your employees, initiate culture-building exercises to support the organizational change, and keep tabs on the resources needed to follow through on the projects.

- Evaluate

After you execute the plan, you should create a report of improvements and get feedback from all the teams that were involved in the execution process. Ask what the performance looked like and whether the goals were reached. Their documentation of failures and successes will be a valuable tool for the future. Make sure you stay transparent and inform the management and the relevant parts of your company about the progress.

- Consolidate

Finally, make sure you analyze the framework of the entire operational excellence process and, this may sound a little meta – figure out if you can make improvements in making improvements! Ultimately, this is what operational excellence is all about – stacking improvements. Be mindful of the changes to the culture of your organization to support future initiatives and figure out what your next project will be.

Operational Excellence Examples

We’ve covered the theory of operational excellence in detail.

But what does this process look like in practice?

Many companies have been successfully adopting the operational excellence methodologies to boost their bottom lines, but there were a few pioneers that deserve a mention the most.

Let’s take a look at some of the early adopters of the operational excellence methodologies.

Toyota

The Toyota Way is the first solidified set of managerial principles and production systems. It was created back in 2001 and was originally called “The Toyota Way 2001”.

This system was a summary of Toyota’s philosophy and values related to manufacturing and it involves principles in two main areas:

- Continuous Improvement

- Respect for People

The rationale behind the creation of this system was simple – it was supposed to be a tool meant for individual employees to improve their work. The system consists of 14 principles divvied up into 4 sections:

Section I – Long-term philosophy

Section II – The right process will produce the right results

Section II – Add value to the organization by developing your people

Section IV – Continuously solving root problems drives organizational learning

So what were the results of the implementation?

Not so great. Toyota Way has been criticized for being an instrument of control, rather than a supporting and benevolent strategy for the growth of employees and the company. Toyota ended up rewarding extreme loyalty as opposed to letting every voice (particularly the challenging ones) participate in the discussion.

As a consequence, the company almost faced a recall situation related to the sudden acceleration issue in some of its vehicles.

The Toyota Way may be a cautionary tale for those who have really high ambitions. Akio Toyoda, President, and CEO of the company admitted himself that the company wanted to “grow too fast” and revealed its aspiration to become the world’s biggest automotive manufacturer, which ultimately led to losing track of the key values.

Amazon

Perhaps one of the best examples of operational excellence in practice is the Amazon and its 14 guiding principles. A company that was founded in 1994 in Jeff Bezos’ garage in Bellevue, Washington is now the 2nd largest company in the world, six years in a row according to the Fortune 500 ranking.

And that’s not everything, because Amazon is still growing at an astonishing rate. The company’s revenue growth was up 21% in 2019, totaling a staggering $281 billion.

Part of the company’s success has been its ability to follow trends and adopt new technology with great potential. This year, the NFT market has grown nearly ten-fold, and its volume now exceeds $2 billion. Amazon’s first NFT investment was in Dibbs, a platform that allows users to fractionalise sports collectibles, like physical sports cards as NFTs. Currently, Amazon is one of the largest companies in the world. Their investment and belief in NFTs may be key to the growth of the space based on the finances they have, as well as the users they have on their platform.

All of this wouldn’t be possible without Amazon’s drive to achieve operational excellence. The company has defined its mission statement in 14 key principles, which are actively and consistently promoted within Amazon’s structure.

Here they are:

- Customer Obsession

- Ownership

- Invent and Simplify

- Are Right, A Lot

- Learn and Be Curious

- Hire and Develop the Best

- Insist on the Highest Standards

- Think Big

- Bias for Action

- Frugality

- Earn Trust

- Dive Deep

- Have Backbone; Disagree and Commit

- Deliver Results

Above mentioned results speak for themselves. It is safe to say though, considering Amazon’s incredible pace, that it is on its way to become the biggest and most successful company in the recent history.

Conclusion

Operational excellence is like a holy grail of management – to achieve it you have to expect that it is going to be a long and tedious process. It requires a lot of experimenting and learning from your mistakes.

It is a price worth paying though, as companies that achieve operational excellence tend to yield the best results and leave their competition in the dust.

Operational excellence can happen anywhere, and you don’t need to be a huge enterprise to make use of it. Many of the methodologies of continuous improvement work just as well in smaller and mid-sized companies, they’re universal for any entity that needs management. That’s why it should be a priority for any business to foster an operational excellence culture from the very beginning.