Business processes are the principal determinant of how successful a business operation becomes. Using this guide, business owners and other stakeholders can initiate business process improvement and optimize for maximum efficiency.

Let’s assume that your business was a house. Your business processes make up the glue or structure that keeps it all together. Without this structure, the house inevitably collapses into unrecognizable rubble.

Every builder aims to put up a steady, solid structure that allows for the most efficiency while possessing the capacity to endure external elements and internal challenges. It often means reviewing business processes to figure out the best ways to improve them.

Improving business processes often seems to be too much work. Granted, it requires some work, but there’s no substitute for developing the habit and making it part of your routine. It’s a way to ensure that your organization’s long-term health is secure.

Throughout this guide, we’ll consider the simple ways to improve your business processes.

What Is Business Process Improvement (BPI)?

Business Process Improvement, or BPI, is the practice of examining all the practices and procedures in an organization to find ways of making them better or more efficient. It primarily increases operational productivity.

In a typical campaign to improve business processes, company managers will come together to analyze each business practice and pick out potential improvement areas. They’ll then make targeted adjustments to specific operations or empower employees to learn critical skills to improve their operations.

Company leaders usually undertake a cost-benefit analysis to determine if the anticipated benefits are worth the potential investment.

Steps for Conducting Business Process Improvement

BPI is a deliberate technique to fix problems and efficiencies within your organization. Using this systematic approach, you can streamline management. Here are six steps for a basic BPI process, although you can modify them to apply in any business.

1. Identifying the problems

First of all, do you know the problem or scope of problems your business is facing? Are you interested in increasing sales? Do you want to improve production? The point is you need to be clear about what the issue is instead of being vague and telling your team, “our business processes need to improve.”

It’s important to identify a specific business goal, such as “grow monthly output of Product A by 15 percent.”

A viable way to identify problems is to ask if you’re unsure. An example will be asking those in sales if there’s anything about the business they prefer another way. As key stakeholders in this regard, you can learn from those in sales about the actual pain points in their line of work.

2. Mapping your current processes

In this step, you’re essentially seeking to understand how your business works now. A flowchart is a useful tool for the mapping procedure. If you prefer, you may also use comprehensive software to improve the details of your process mapping.

Map out your business processes so that you have the best possible view of how your business operates. When you’re done with this, provide a plan to fix the problems.

Paper flowcharts work well for simple business processes with only a few points. However, project management software can help you capture more details crucial to fully understanding the processes.

There are software applications that support detailed business process mapping. Some of these open-source software, meaning you can tweak them to suit your organization’s needs (if you’ve got the programming chops to do so).

3. Analysis

Once you’ve adequately mapped a process, you need to thoroughly analyze it to surface all inherent inefficiencies. Then, again, you need to ask the right people questions. You’ll be right to ask why the production of a certain raw material is down, for instance.

You can probe further by asking when your production runs into problems. Can you do anything to fix the problem(s)? In what way(s) will it affect the project budget? How about deliverables? These are possible touchpoints you’re likely to address during analysis.

It’s advisable to discuss several possible solutions with your team instead of focusing on one solution to the problematic process. Then, bearing your context in mind, you can test each proposed solution with your team. Of course, your preferred solution may solve your problems to a large extent. But, you’ll often discover that another solution is more comprehensive or has certain advantages that work better for your business.

4. Process Redesign

As soon as you conclude the process analysis step and surface the problems within, you begin to patch the inefficiencies. Before you apply any fixes, it’s best to perform a risk analysis to ensure that your streamlining isn’t going to introduce new problems.

It’s advisable to talk with your staff to work out any blind spots and ensure you have a workable solution. Make each level of change a small manageable one that you gradually increment. It gives the team time to adjust and allows you to make a U-turn if things don’t go as planned.

5. Implementation and monitoring

All the steps above don’t matter if there’s neither the will nor resources to implement them. As you monitor the execution of the new process, be sure to actively monitor change, especially at the beginning stages.

It’s important to take note of any positive or negative shifts in numbers. Instead, your primary question should be why you’re getting the results you’re getting. Then, keep tweaking things until the desirable numbers are more frequent.

It’s important to maintain open communication lines with employees. It matters because your employees are likely closer to the situation than you are and will possibly identify execution problems and interpret their ramifications better.

Common implementation issues include employees having a hard time adapting to the new system or a new challenge developing elsewhere on the assembly line.

6. Reflection and Benchmarking

Once the new business process is in place, you should let it run for a while, say a few months. It allows sample data to build up that will enable you to review the process change in a thorough and objective manner.

Data crunching follows immediately after you have enough sample points. This can take time and is usually rigorous – the higher the detail, the better. Once you have the results of the data analysis exercise, get your team in a huddle and pore extensively over the results.

Just as with process mapping, data collection during the new process execution is more comprehensive when you use software. This helps generate reports and provides important reference points for team reviews of the new process. Here, you’ll gain important insights that will help enhance the new process.

Business Process Improvement (BPI) Methodologies

We’ll now explore a few business process improvement methodologies that can help your team to reduce inefficiencies. The methodology you choose to adopt at your organization is relative to why you want to improve the processes and what you aim to improve. Though some methodologies are more popular than others, there’s neither a single best one nor a one-size-fits-all solution.

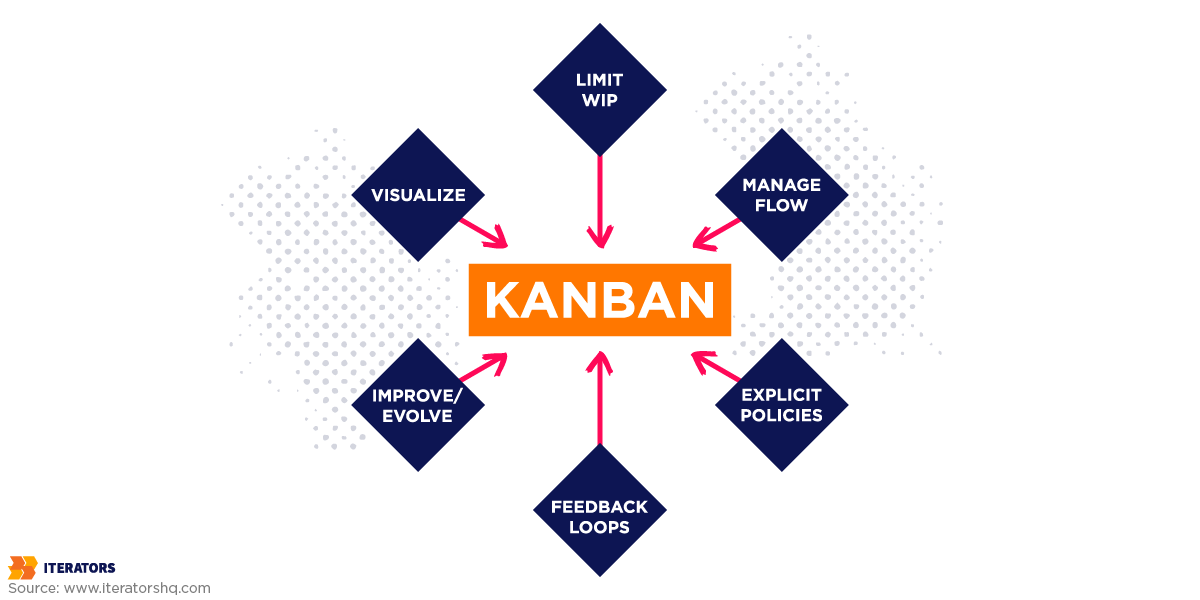

1. Kanban

The term “kanban” will be familiar if you’ve ever dipped your toes in the waters of project management or enterprise resource planning (ERP). Being of Japanese origin, the word literally means “billboard” or “card.” The Kanban system derives from the “just-in-time” delivery model of supermarkets and was created in the 1940s by Toyota’s engineers.

In preference to ordering products to restock shelves based on vendor availability, current store inventory determined the placing of orders. Toyota’s engineers applied this model to manufacturing by matching inventory with demand and increasing quality and throughput.

Kanban is helpful for visually organizing production using cards. Each card represents a task or step in the production process. For example, manufacturing floor workers would receive containers containing a Kanban representing steps in the manufacturing process. Kanban cards also became the communication mechanism between adjacent workstations. The enhanced productivity helped make Toyota the most profitable automobile manufacturer in the world.

The work of David J. Anderson, Corey Ladas, and several others helped adapt Kanban for use in software development. The system focused on making incremental changes to processes and systems and could be adapted across different organization types.

Kanban is essentially a “pull” system with minimal work-in-progress to minimize bottlenecks or drag in the process that prevents supply from matching demand.

Considering the software industry origins of modern Kanban, the existence of electronic Kanban, or e-Kanban, systems is by no means surprising. It is common in ERP software and project management software. They include attachments, barcodes, and other forms of electronic messaging.

The original six rules that guarantee a successful Kanban implementation are as follows:

- Downstream processes use items only in quantities that the Kanban card specifies.

- Upstream processes produce items only in quantities that the Kanban card specifies.

- Nothing is made, moved, or changed unless a corresponding Kanban card exists.

- There must be a corresponding Kanban card for every item produced or shipped.

- Defects, errors, or shortages never belong in the downstream pipeline.

- The total number of Kanban cards remains limited to minimize inventory or work-in-progress while shining a spotlight on bottlenecks in the process.

The benefits of Kanban and its adaptability to improve business processes across industries are well-documented. It works in improving business processes for any product-generating team.

However, the learning curve for Kanban is often steeper than most teams anticipate if they’re transitioning from the traditional waterfall model. Other than that, your team will be able to reduce lead times, increase communication, and grow output once they become familiar with Kanban.

2. 5S

The Japanese may be aptly described as pacesetters in process improvement. Besides Kanban, they also pioneered the 5S methodology of lean that ensures workspaces are clean, clutter-free, safe, and well-organized to minimize waste and optimize productivity.

Clean workspaces reduce the probability of injury and the tendency to waste time.

The 5S system is suitable for visual control and lean production, creating a work environment with high physical and mental quality.

Five Japanese words – seiri, seiton, seiso, seiketsu, and shitsuke – make up the vertices of the 5S pentagon. These words also have English equivalents that begin with the nineteenth letter of the English alphabet. They are sort, set in order, shine, standardize, and sustain.

Each S is a part of the five-step process that can improve the overall business operation.

Sort

This first step assesses every item in the work area to determine what should (and shouldn’t) be present.

Set in order

With much clutter out of the way, you can now group people, items, and workstations in the most logical way for the organization.

Shine

It’s advisable to clean the work area, including performing maintenance on equipment and machinery. It’s easier to anticipate problems and prevent breakdowns with planning. In addition, it reduces time wastage and loss of profits due to work stoppages.

People tend to become more invested in the business when they take responsibility for shining their workspace.

Standardize

The first three steps of 5S bring about significant improvement in organizational processes. But there has to be a way to sustain this over the long term. That’s what Standardize achieves. It provides a system where one-time efforts become entrenched habits.

Sustain

Once our standard operating procedures for 5S are in place, your organization needs to maintain them and regularly update them. Sustain keeps the 5S wheel chugging nicely forward while ensuring everyone is involved. It helps to make the initiative more than an event, in other words, a culture.

3. Plan Do Check Act (PDCA)

Positive results are inevitably noticeable when businesses sustain 5S for a long time.

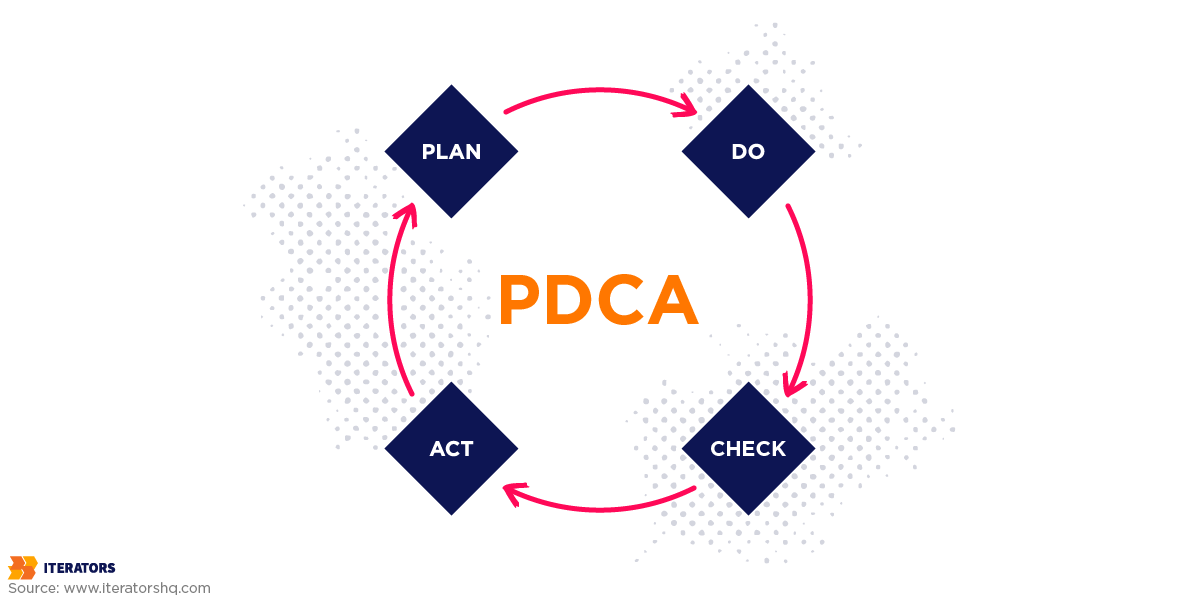

Solving problems can be an interactive process, and that’s what the PDCA cycle achieves in process improvement. PDCA improves processes and also implements change. Walter Shewhart created this process improvement method when applying the scientific method to quality control. W. Edwards Deming would significantly improve Shewhart’s idea by using it in tandem with elements of quality control.

There are four principal steps to the PDCA cycle. These include:

- Plan, where you determine the problem to solve and develop a plan to solve it.

- Do, where you test and implement the plan in controlled circumstances.

- Check, where your organization reviews the performance of actions from the Do stage.

- Act, where your organization decides whether to implement change at scale after reviewing test outcomes.

PDCA is essentially a process improvement cycle; therefore, your organization can iterate the steps until it achieves suitable outcomes.

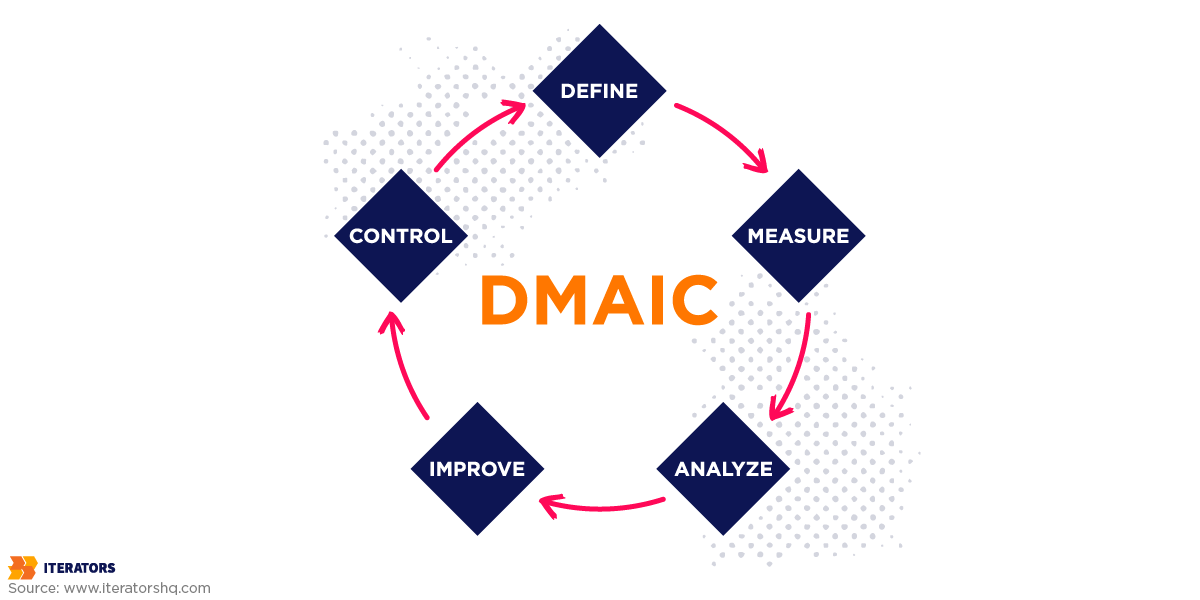

4. Six Sigma

Six Sigma is a process improvement methodology that has gained steam in recent years. Its main aim is to leave as few variations as possible in the final product.

The brainchild of Bill Smith, a US-born Motorola employee, Six Sigma employs statistical data benchmarks to help business leaders fully understand the performance of their processes.

Under Six Sigma, a process is optimized only if it produces less than 3.4 defects per million cycles.

The application of Six Sigma is common in manufacturing, primarily because it helps to minimize defects and inconsistencies. In order to significantly improve customer satisfaction, Six Sigma’s goal is to optimize for consistency.

The two main processes used in Six Sigma include:

- DMAIC, for existing processes.

- DMADV, for new processes.

DMAIC stands for:

- Define the opportunity for improvement, that is, the problem.

- Next, measure the performance of your team’s existing processes.

- Third, analyze the current process to reveal defects and their root causes.

- Fourth, improve each process by addressing root causes.

- Finally, control the improved processes and assess future process performance to handle deviations.

From the steps here, it’s obvious that DMAIC prioritizes the analysis stage. During this stage, teams employ an Ishikawa diagram or fishbone diagram to help them visualize the possible causes of each product defect.

The head of a fishbone diagram outlines the initial problem. At the same time, each rib along the fish’s spine lists various categories of issues that can cause the initial problem.

This visual analysis method is an excellent way to identify the issues that may arise from a single root cause.

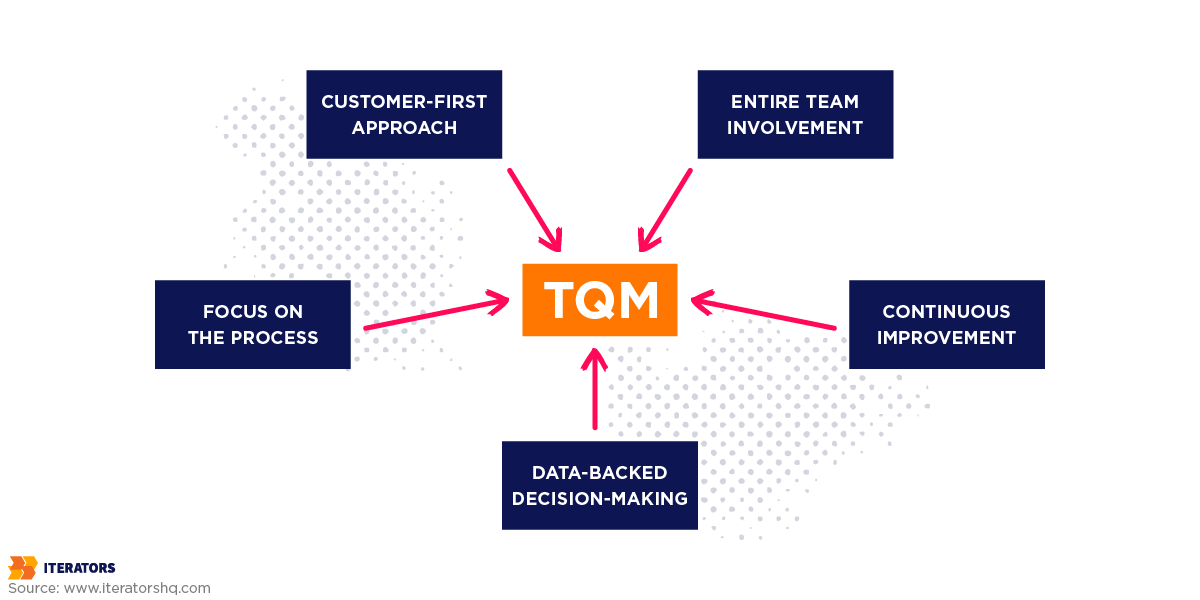

5. Total Quality Management (TQM)

In applying continuous improvement over time to enhance the customer experience, many organizations use the Total quality management or TQM process improvement method. This technique is common in supply chain management and customer satisfaction initiatives.

The focus of total quality management is data-driven decisions and performance metrics. When attempting to solve the problem, success metrics help you to decide how to improve a process.

These are the key characteristics of TQM that you need to know:

- It is a customer-first process improvement methodology. The satisfaction of the customer is always the principal consideration in TQM. In order to improve quality, your team will seek to understand how the process change may affect how consumers experience your product.

- It involves the entire team. Whereas other process improvement methodologies only involve a few team members (mostly from production), TQM needs all hands on deck. Therefore, you’ll also optimize, in tandem, more business-centric processes such as marketing and sales to improve the satisfaction of the end user.

- It is about continuous improvement, which aims to make small changes to processes over time with the objective of constant optimization. Business comes with much variability, and continuous improvement is one way teams can adapt as external circumstances change.

- It involves data-backed decision-making. Data is the centerpiece of modern process improvement. Therefore it’s important to collect it on as many fronts as possible. Data can help your team spot locations of inefficiency and enable you to channel resources to the appropriate areas in the process pipeline.

- It focuses on the process. Total quality management has a primary goal of improving processes. Whereas other process improvement methods aim to minimize defects, TQM drastically addresses inefficiencies.

Key Benefits of Business Process Improvement

Inefficient business processes cause organizations to progress at snails’ pace. Here are a few of the well-known benefits of improving business processes:

1. Increased operational efficiency

When you automate business processes in order to improve them, you inevitably gain efficiency points. The attendant benefit of this is that you also lower your operational costs. One McKinsey study revealed that organizations could save between 10 percent and 15 percent of their operational costs by using workflow automation tools.

Those are conservative values, however, when we consider that organizations have reported savings of millions of dollars per year after investing in workflow automation software.

Some tools enable your team to create workflows and leverage end-to-end visualization of processes. For example, consider an organization looking at its employee onboarding for possible improvement.

The onboarding process typically requires the completion and submission of necessary forms. Unfortunately, most companies still go the manual route to achieve this, and employees continue to wonder if it can’t be done differently. They’re right; automation streamlines the process, allowing new staffers to hit the ground running in roles they receive salaries for.

2. Improved employee productivity

Inefficient processes are a cancer. They don’t just disrupt the normal functioning of your organization. They also impact your people by ensuring they do less meaningful work due to an excessive focus on repetitive and time-consuming tasks.

Over 40 percent of employees spend 25 percent of their working time on repetitive tasks. To be sure, manual data entry happens to be the most implicated culprit.

However, business process improvement software can automate data entry using auto-populated form fields. As a result, employees can spend far less time on manual data entry and more time on other more productive tasks.

When your organization improves its business processes like this, one of the benefits is that everyone knows who’s responsible for specific tasks. As such, you can build a workflow to ensure only the right recipient receives a particular form. Thus, employees won’t wonder who should receive the form.

3. Minimal occurrences of human error

Paperwork of any kind is often tedious to deal with. But, it seems the bigger problem is the high margin for error when working with them. Imagine sending out correctly filled forms to the wrong party. How about incorrectly filling the forms and sending them to the right individual? Both scenarios are not desirable.

Financial losses are just one type of outcome in these situations. Few people are aware that spreadsheets are prone to errors. For instance, the London Olympic Committee sold 10,000 more tickets than it should have when an employee entered “20,000” into a cell instead of “10,000.” In the spirit of the competition, the committee upgraded ticket holders to other major events. Whose loss? Your guess is as good as it gets.

A switch to automatic calculations is a form of process improvement that you may embed in your forms. This approach minimizes the possibility of human errors arising from manual data entry.

Business Process Management (BPM)

Your business is like a living organism. Therefore, it grows and morphs over time. Your team might have developed a process that once worked excellently but has developed mysterious issues lately. That shouldn’t be too surprising as the circumstances were likely different at the earlier time.

As your operation grows, however, those processes may tend to lag, subtracting vital efficiency points from your team.

Business process management is an important tool for three things:

- Identifying kinks in your workflow.

- Identifying means to automate manual work.

- Identifying strategies to reduce inefficiencies.

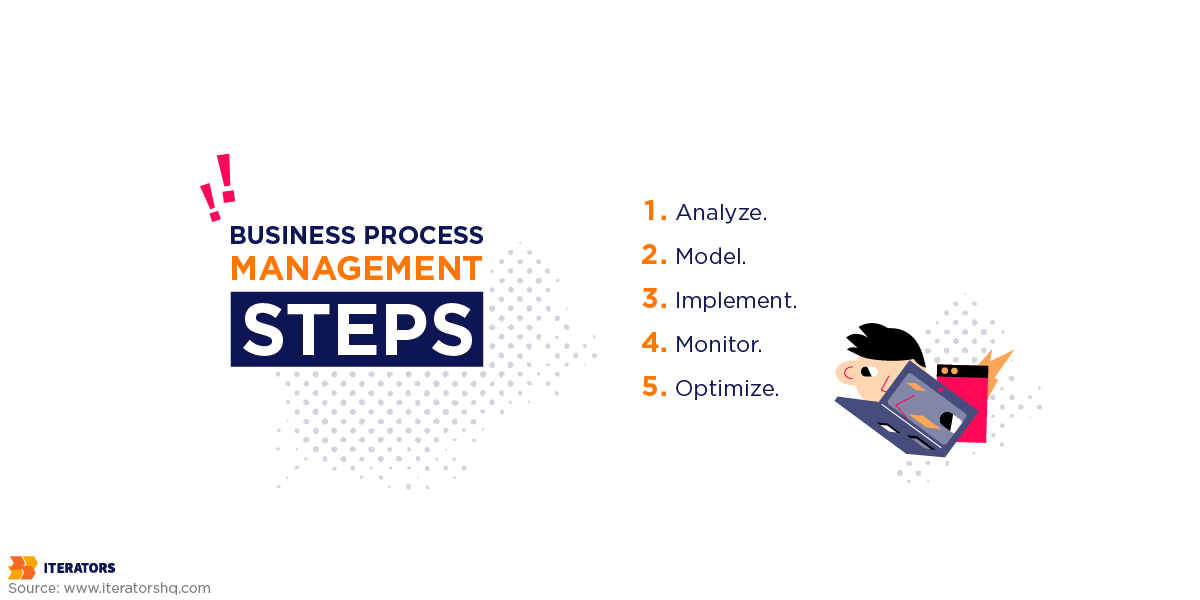

There are five principal steps to business process management, including:

- Analyze: Conduct process mapping, that is, review your current practices and map their full scope.

- Model: Make a draft of your expectations for the new process. Therefore, if you notice any inefficiencies in the first step, you can outline possible ways to resolve them during this stage.

- Implement: Now, it’s time to put your model to the test. You need to remember that establishing key success metrics will help you determine whether your changes were successful.

- Monitor: You then decide, through monitoring, whether your project is successful. The success metrics identified during implementation should ideally be growing.

- Optimize: As your process evolves, you need to keep an eye on possible inefficiencies in the process, optimizing as you go along.

Business Process Improvement (BPI) vs. Business Process Management (BPM)

It’s common for people to wonder if business process improvement is the same as business process management. However, the two concepts are different. While BPI pays attention to specific process points, business process management, or BPM, aims to analyze and improve business processes.

Now that we have taken a short excursion into the world of business process management, we’ll now take an in-depth look into how BPM differs from BPI.

To begin with, the latter focuses on increasing customer value by improving quality. It also enhances service, lowers costs, and raises the productivity of activity or business processes.

BPI initiatives extensively use popular techniques such as Global 8-D, Lean, Six Sigma, and Rummler Bache. These methods aim for either small improvements over time or wholesale “breakthrough” improvement which is essentially a new way to manage the business.

On the other hand, BPM is a disciplined approach to management and methodology that provides an in-depth understanding of the entire process, visibility, and control to ensure effective communication across an organization.

In many companies, BPM is actually an aggregation of BPI, performance management, and organizational change management with technology to ensure those process improvements are both sustainable and successful. This unique approach to BPM also ingrains a culture of excellence across the organization.

Depending on the organization, BPM may be either a process or technology. Yet, there are a few where BPM is a blend or convergence of process, people, and technology. This technology aspect brings us to the subject of BPMS (Business Process Management Solutions).

BPMS introduces technology into the BPM equation by making available a platform for modeling, managing, optimizing, and rapidly adjusting business processes. In addition, these technology tools are useful for solving multiple process-related issues via automation, collaboration, and visibility.

The two main purposes that business process management solutions achieve include:

- Process-based or Process improvement: In order to transform individual end-to-end processes, build agile workflow solutions by taking advantage of process modeling, workflow automation, and process analysis.

- Technology improvement: In order to make more comprehensive functionality available to teams, provide a workflow engine to power bespoke applications.

BPMS introduces a “process layer” to an organization, thus removing silos of applications, data, and people that business processes operate in. The implication is that BPM plugs the holes between the silos.

Depending on how established your organization is, its needs, and its goals, either BPI or BPM is helpful to improve operational performance in order to address productivity, quality, cost, and the full scope of customer experience.

However, it’s necessary to note that BPM is more transformational as it comprises understanding, visibility, and control.

Conclusion

Clearer processes and improved workflows should be a primary concern for team leads in your organization. Besides lowering inefficiencies, business process improvement can potentially raise your teams’ productivity to surreal levels.

It takes a mix of science and creativity to find the fault lines in your business processes. Plus, a broken business is a recipe for losing unpredictable amounts of time and money.

Indeed, process improvement is now a discipline in its own right. Yet, considering that it is more of a business concept than a job role, several job titles fall under the umbrella of process improvement.

1 Comment

This article is very insightful and relevant for anyone who wants to improve their business processes and achieve better results. I know how important it is to have efficient and effective business processes. I agree with the article that you need to identify the problems, analyze the current state, design the future state, implement the changes, and monitor the outcomes. I also liked the examples and tools that the article provides, such as the SIPOC diagram, the Pareto chart, and the PDCA cycle. Thanks for sharing this valuable information.